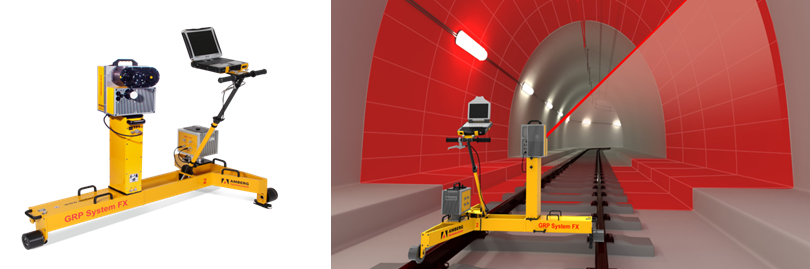

GRP IMS5000 Tunnel Scanning System

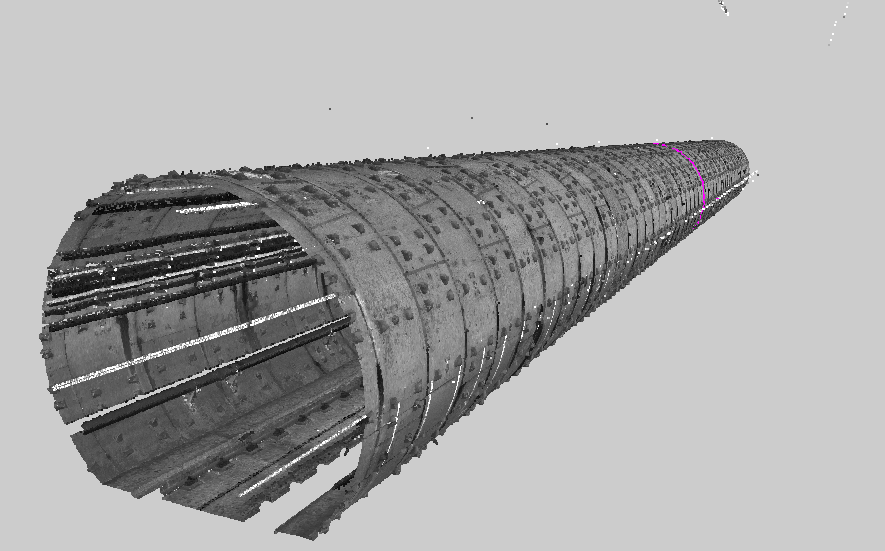

IMS5000 adds inertial navigation module on the basis of GRP5000, and records line track while scanning, which can quickly and efficiently complete the three-dimensional data collection of track and surrounding structures, buildings (adjacent track, tunnel, overhead line, etc.) information. In addition to all the function modules of GRP5000, the system can also be used to fit the central coordinates of shield tunnel, the central coordinates of line, identify the height of overhead line, and identify the information of the approach rail head.IMS5000 collects real 3d data and can also be used to provide data foundation for 3d information visualization, virtual reality and BIM modeling.

IMS 5000 Tunnel Scanning System Full Section Scanning & Track Date Acquisition

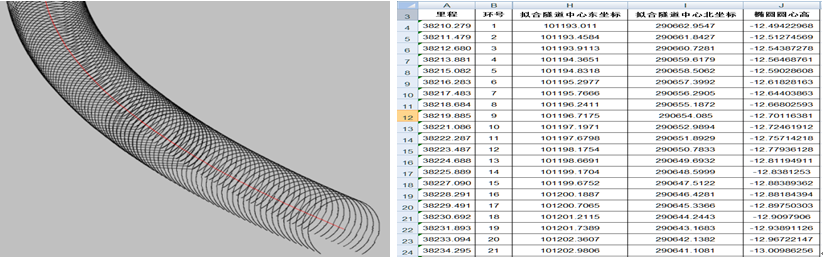

Fitting The Tunnel Center Line

The central coordinates of shield tunneling can be automatically fitted and extended to CAD drawings,which can be used as the results of planning and completion acceptance.

Track Center Line Coordinates

The center line coordinates can be automatically generated and expanded into CAD drawings, which can be used as the results of planning and completion acceptance.

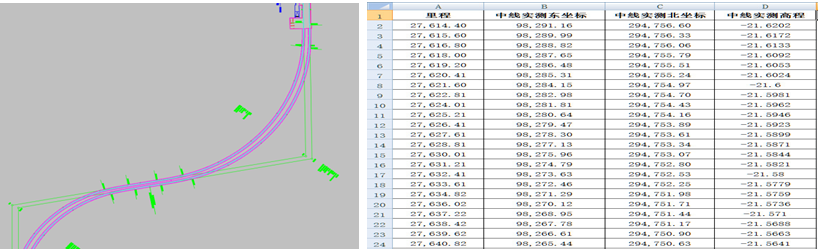

Height and Pull Out Value of Contact Network

It can automatically identify the contact network, generate the height and pull out value table and generate CAD format file

Identify the Rail Head Information

It can automatically identify the rail information and output the rail gauge, the rail line center coordinates and other parameters. It can identify the third rail and generate the position information of the third rail.

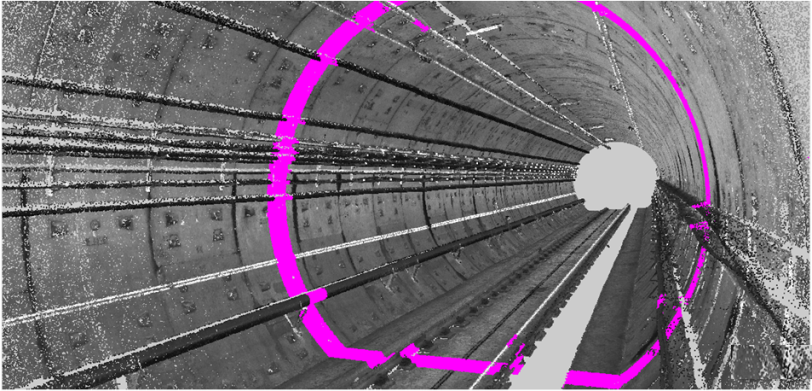

3d Visual Virtual Reality

The 3d absolute data collected can be browsed in the software and can be exported to point cloud of various common formats for virtual reality, BIM modeling and so on.

IMS5000 Working Site IMS5000 Working Status

TGS FX Manual Rail Inspection Trolley | Hardware for Tunnel Map | ||

Stationing | Photoelectric counter measurement method | Laser scanning device for tunnel surface scan | High speed phase laser scanner |

Mileage resolution | ±5mm | Scanning frequency | 200Hz,Multistage optional |

Gauge(mm) | 1000,1067,1435,1520/24, 1600,1668/76 | Points per profile | 2500/5000/10000/20000 points per profile |

Range of measurement | -25mm/+65mm (Contact displacement sensor) | Image scanning speed | 3.6/1.8km/h (resolution 5mm*5mm ) |

Measurement accuracy | ±0.3mm | Clearance scanning speed | <5km/h (resolution 20mm*20mm ) |

Super elevation | High precision obliquity sensor | Scanning distance range | 1-119m Laser carrier phase shift measurement principle |

Range of measurement | ±10° (±224mm at gauge of 1435mm) | Object recognition accuracy (in distance of 5m) | ±3mm (relative), ±5mm (absolute) |

Measurement accuracy | ±0.5mm (At gauge of 1435mm) | Profile accuracy (in distance of 5m) | ±3mm |

AMU1030 | Job site environment | Lighting: no requirement ; Temperature:-20° +50°;Humidity:80%, no condensation | |

Data update frequency | 100Hz | Tamping truck type | DC32,DCL32,DWL48 in WINALC operation system |

Measurement accuracy (horizontal and vertical) | 0.1mm RMSE (10m chord) | Measuring speed | The same as scanning speed |

0.5mm RMSE (30m chord) | Measuring accuracy | 1mm (ignore CP3 error) | |

1mm RMSE (70m chord) | System weight | 61kg | |

Previous: GRP5000 Tunnel Scanning System

Next: TunnelMap Tunnel Mapping and Information Management Software