Home>>About us

First, application background

Compared with the interval line measurement, the station area ballast measurement has the following characteristics: higher precision requirements, wider gauge, tighter tip rails, and guide rail switching. The number of new line switches and the number of models are numerous, and the measurement tasks of the interval lines are heavy, which puts higher requirements on the accuracy and efficiency of the measuring equipment. In this context, the Hangzhou Works Department newly purchased a GRP1000IMS equipment and fine-tuned the drums in the Hanghuang Railway (in the section of the Shanghai Railway)

Second,application overview

Scope of operation: Hangzhou South Line, Yangcun Bridge Line, Fuyang Station, Tonglu Station, Qiandaohu Station, Jiande Station, and section lines;

Switch model: CNNT18# turnout, CNNT42# turnout, domestic 18# turnout;

So far, the long-track static fine-tuning drum operation using the GRP1000IMS equipment has been completed, and the joint adjustment test is underway.

Third, measurement operations

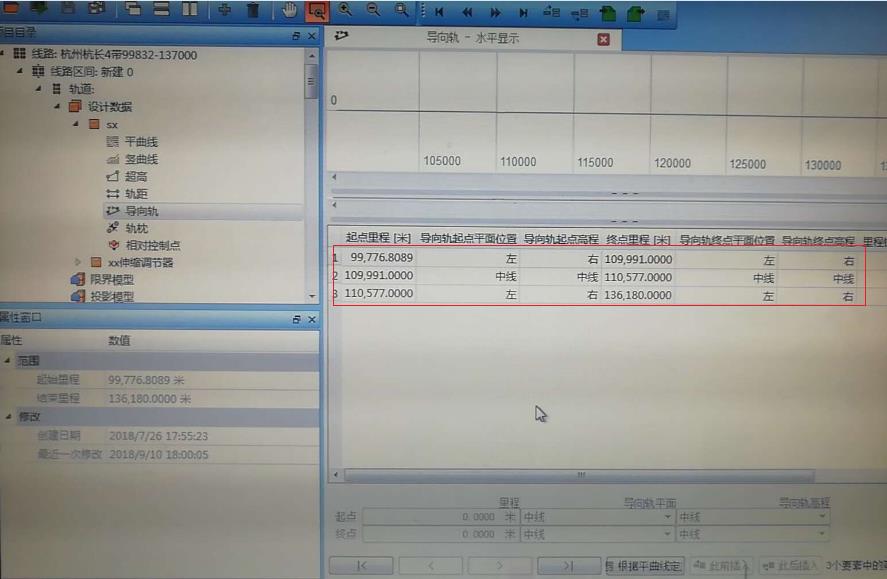

1. Since the measurement range includes the helium zone, the gauge and guide rails are manually defined.

Ø Gauge: The widened area is divided into the left and right sides of each sleeper according to the mileage. The non-widened area defines the mileage range according to the flat curve, and the gauge is 1.435.

Ø Guide rail: Manually define the straight-point rail as the plane guide rail according to the mileage range of the switch (the ballast is extended according to the actual situation before and after the turnout), and the interval track is customized according to customer requirements.

2. GRP1000IMS is a relative plus absolute measurement principle.

Inertial navigation is used to measure the three-dimensional trajectory of the track; the gauge is measured by the trolley and the super-high; the total station is used for the non-leveling every 60 meters (no flaw) / 120 meters (with flaw) Absolute positioning of the trolley, after the end of the operation, the raw data is pre-processed by software to obtain the measured three-dimensional absolute coordinates of the orbit.

Ø Measurement mode adopts multi-point constraint

Ø Set the station requirements: the number of control points involved in the calculation is not less than 6, the mesh shape is better, to ensure that the trolley has points before and after

Ø The speed of implementation should not be too slow or too fast, it is recommended to 1.5~2.0 m / s

Ø Try not to return or stagnate for a long time during the implementation process

Fourth, data analysis

1. The software can export various styles of reports according to the needs of on-site operations.

Hang Huang performs large-scale gongs and drums on site, and the software exports corresponding GEO linear files, VER dialing data files, SYN control point mileage files.

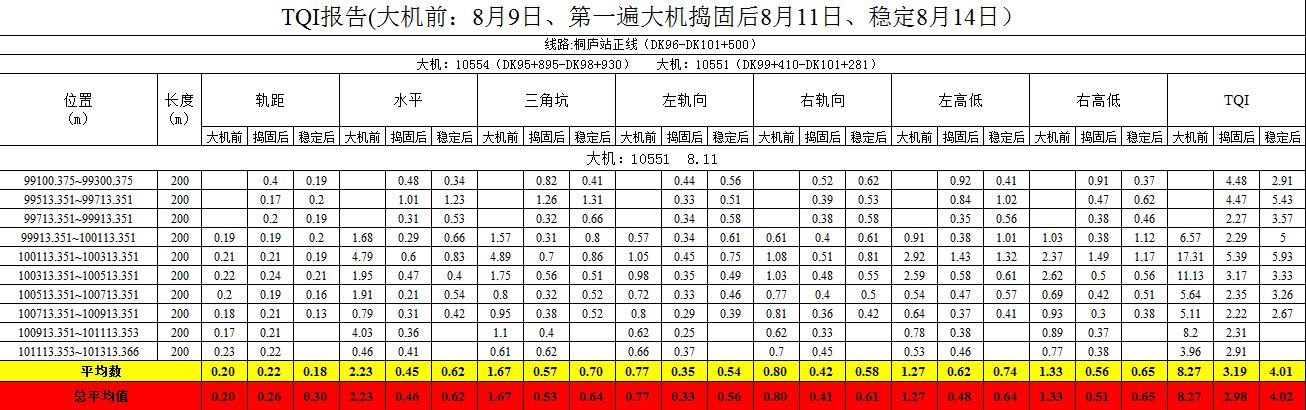

2. Guide the drum operation according to the measured data, compare the TQI before and after the drum.

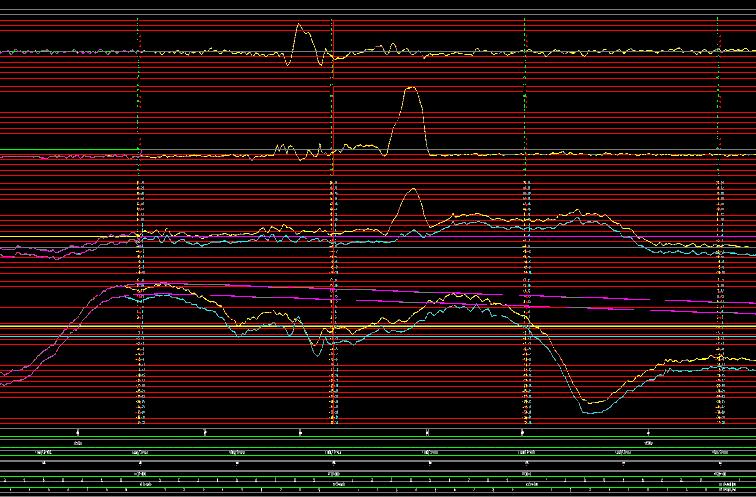

3. Comparison of measurement data between GRP1000IMS and Shanghai 4D in the same section

N6 Road (Amberg) N6 ballast (four-dimensional)

Amberg: lowest point: DK137+889 (-6mm) highest point: DK137+875 (5mm)

Shanghai 4D: lowest point: DK137+890 (-7mm) highest point: DK136+872 (7mm)

Analysis: The line shape and the highest and lowest points of Amberg and the Shanghai 4D solution are basically the same, with a difference of 1~2 mm.

Fifth, conclusion

Through the comparison of TQI before and after the gongs and drums, it shows that the trolley guides the big machine gong and drum effect is obvious, and meets the requirements of high precision and high efficiency under different working conditions, no matter from the field measurement operation or the internal data processing, greatly simplify the operation process, help The public surveyor has improved work efficiency.